Custom

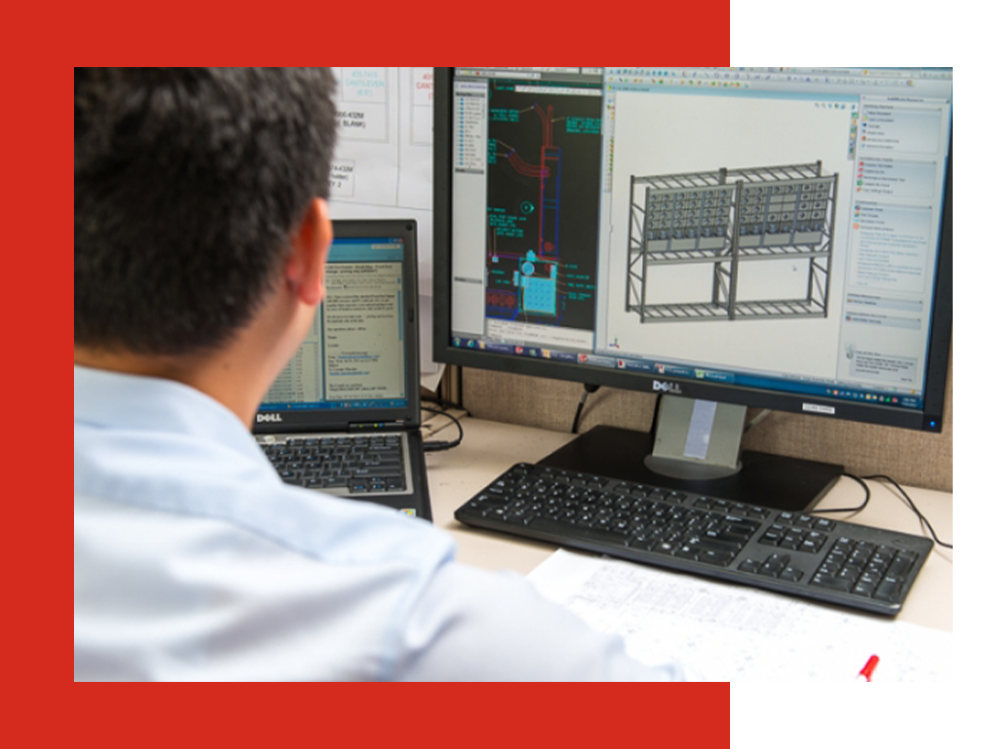

Let our design, engineering and manufacturing experts help you with your next project

Boston Group, founded in 1937

Boston Group, founded in 1937, offers an experienced and dedicated design, technical engineering and manufacturing team to assist you from part design to full production. Our facility houses the very latest in design and manufacturing software and equipment to turn your parts around quickly from concept to prototyping to finished product.

Boston Group provides design, fabrication andfull-service manufacturing of parts, sub-assemblies and finished assemblies with packaging and shipping. Fabrication includes CNC fabricating, CNC laser cutting of sheets, & plate, MIG, TIG spot welding, CNC machining, sheet & plate fabrication, powder coating, Custom packaging & kitting including bar coding, hardware & instructions. UL and Dekkra certified QC & inspections.

Our success is measured by our customers’ ability to realize cost savings. Allow us to show you how we can dramatically reduce your costs and improve your bottom line. We welcome all inquiries and look forward to serving you.

300,000+ square feet of manufacturing, welding, finishing, assembly, packing and shipping space to meet all of your needs

Capabilities

Materials

- Steel

- Stainless steel

- Aluminum

- Plastic

- Brass – up to 1/16” thick for laser

- Bronze – up to 1/16” thick for laser

- Nomex

- Cork

- Polycarbonate (Lexan™)

- Acrylic

- Rubber based materials

- Copper – punch only (no laser)

Materials

- Steel

- Stainless steel

- Aluminum

- Plastic

- Brass – up to 1/16” thick for laser

- Bronze – up to 1/16” thick for laser

- Nomex

- Cork

- Polycarbonate (Lexan™)

- Acrylic

- Rubber based materials

- Copper – punch only (no laser)

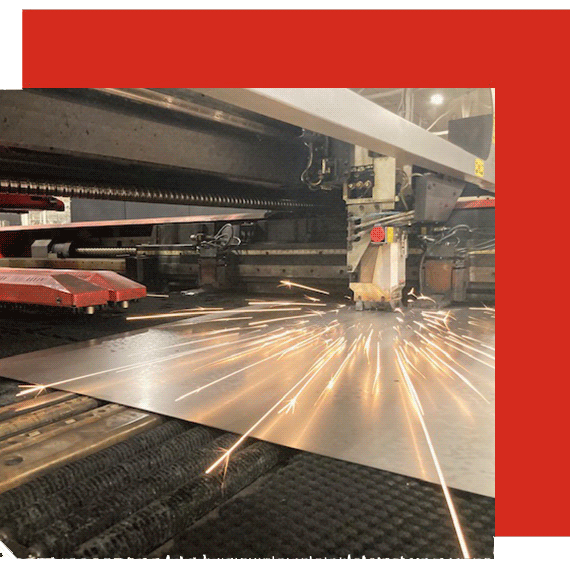

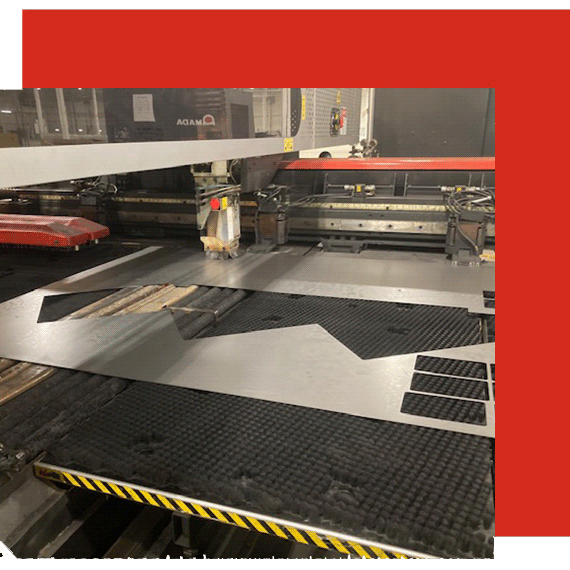

Metal Fabrications

Boston Group offers comprehensive laser cutting services for short and long production runs. Our laser cutting systems have nested laser cutting capabilities, which ensure minimum material waste. Laser cutting technology that eliminates burrs, ensures precise cutting, and reduce the need for secondary operation on the laser-cut part. Turnaround times are extremely quick.Our team can laser-cut almost all materials including stainless steel, wood, and plastics.

Sheet Metal Fabrication

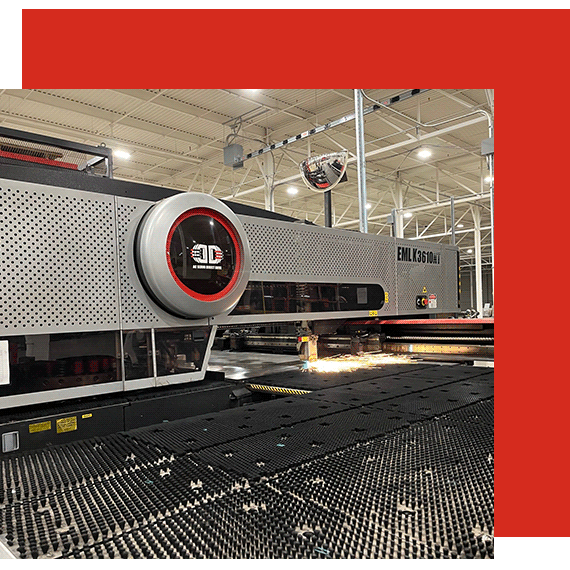

The EML K3610NT specializes in high-speed automated production of small quantity sheet metal parts, especially those that incorporate forming allowing many parts to be completed in a single setup. It manufactures parts with minimum setup and maximum machine utilization.

It can process metal sheets up to 120” long x 60” wide and up to 0.135“ thick gauge and automatically load/unload sheets and components. It has punch/laser-cut capability and can produce smooth cuts and curves.

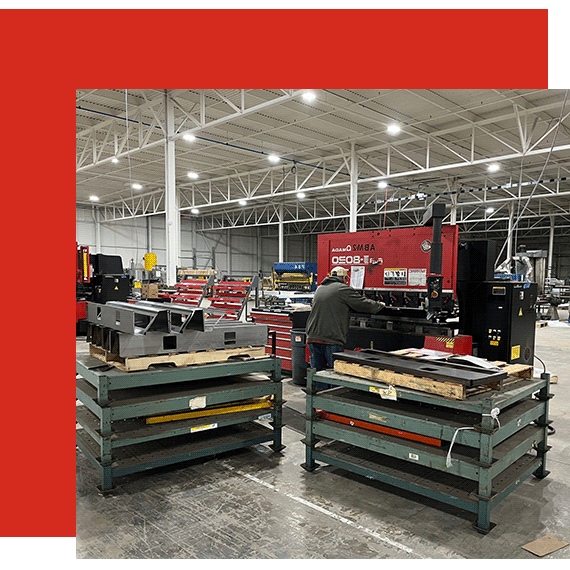

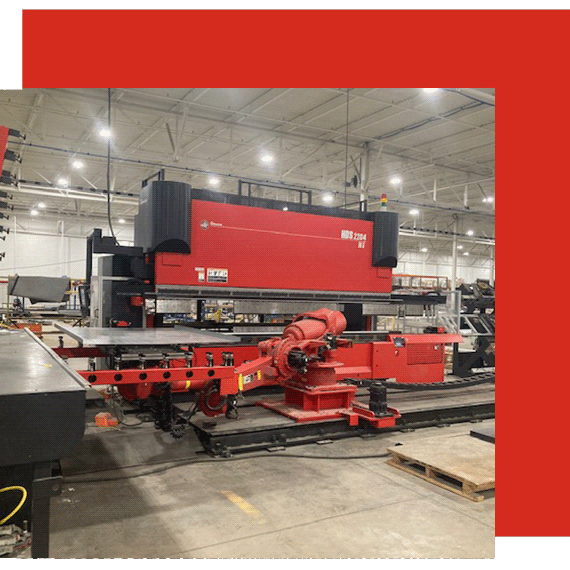

Forming - Manual and Automatic

Boston Group uses CNC press brake machines driven by CAD/CAM programming for precision bending and forming of sheet metal parts that adheres to customer requirements and specifications. Our CNC press brakes are capable of bending and shaping sheet metal with capacities up to 175 tons, and our systems are equipped with a 9 axis back gauge to ensure repeatable positions.Programmable CNC controls in our metal forming systems have the capacity to store up to 100 programs, each having 100 steps. With the help of our comprehensive set of in-house dies, including radius dies and hemming dies, we can produce most parts in a short time.

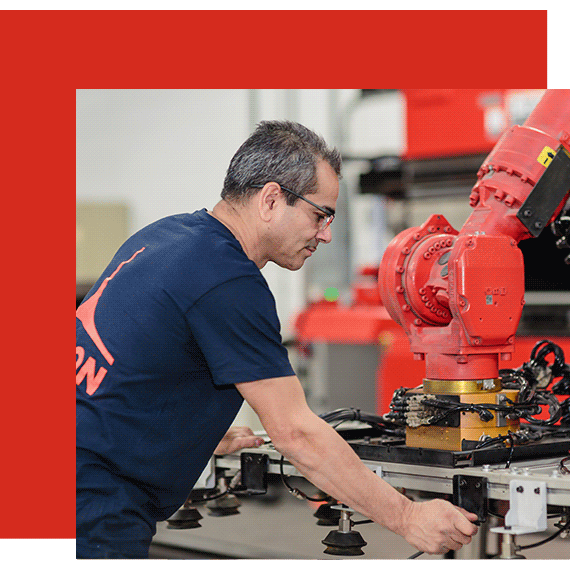

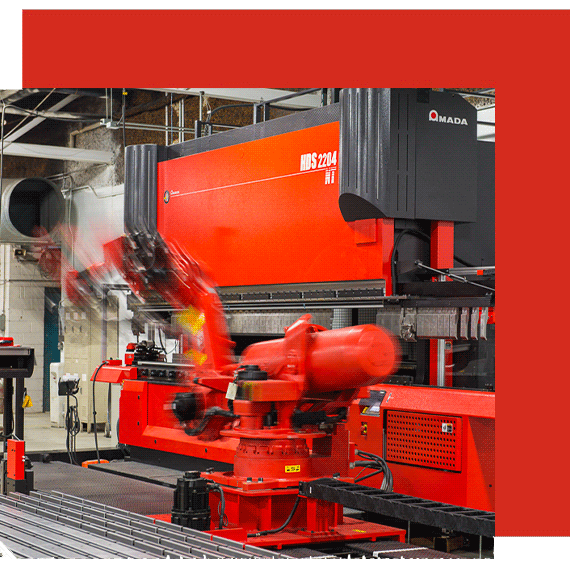

Astro 165 Bending Robot

( Boston Group has one of the only TWO largest of these machines in the country! )

This fully automated robotic arm combined with the electric/hydraulic, down-acting press brake system delivers consistent superior accuracy. The system's super-accurate ram is capable of repeatability to within tolerances of ± 0.00004". The robotic arm can lift large or heavy panels of 30lbs or greater and run without an operator during the day.

• High tolerance for repeatability and accuracy

• Maximum automated part size is 59” x 157” weighing up to 364 lbs (can manually bend parts up to 168” long

• Any type of metal – high tensile strength materials need a large inside bend radius 3X material thickness or better (a property of the material not the machine)

Welding Services

We have a range of welding services, which includes metal inert gas (MIG) welding, tungsten inert gas (TIG) welding, and spot-welding operations. AWS D1.1-certified welders perform all of our manual welding operations.

Our welding operations can be carried out on a diverse range of materials, including stainless steel and aluminum in an assortment of sizes ranging from 1/4-inch bars to 50-foot frames.

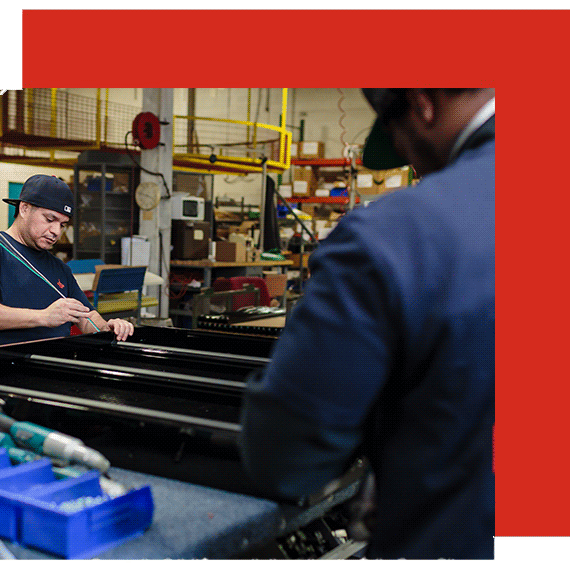

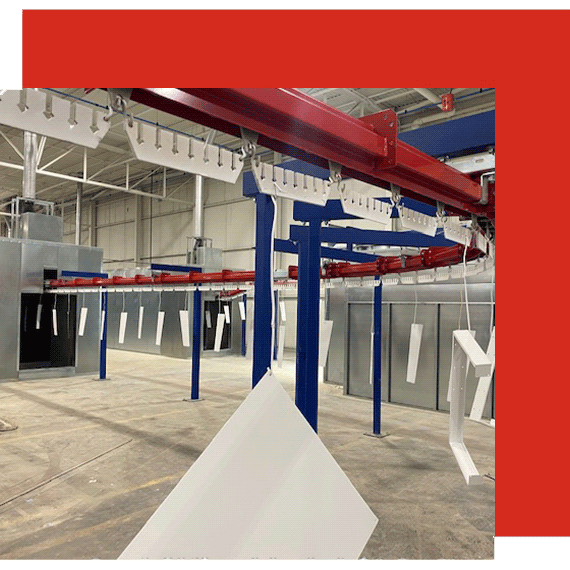

Painting, Assembly and Kitting

Our recently increased manufacturing space and capacity facilitates any size runs, offering faster lead times with increased efficiency.

• A new advanced paint line allows unlimited options for colors

• We offer a state of the art assembly, testing and kitting area

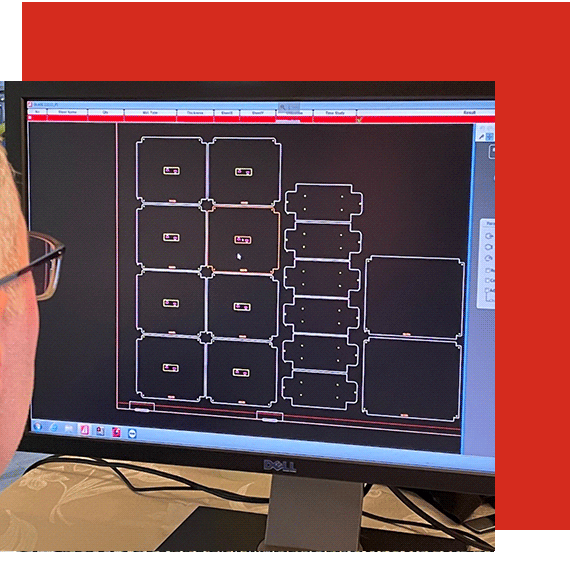

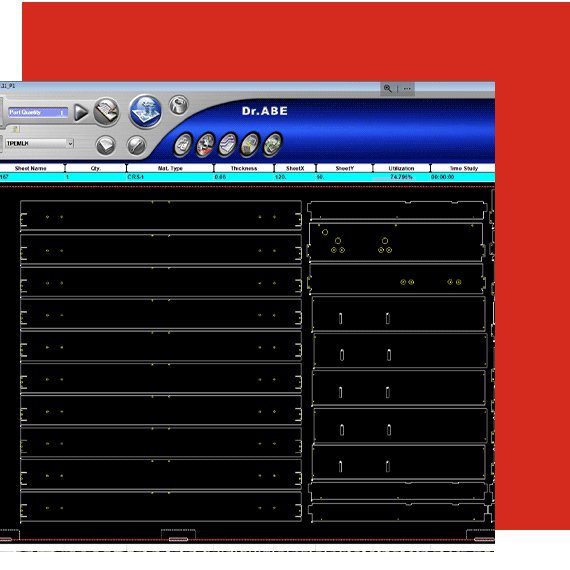

Boston Group also provides reverse engineering solutions with the help of CAD/CAM-enabled laser cutting systems. Our reverse engineering team helps us to create quick drawings from old parts and templates. Furthermore, our CAD/CAM systems also ensure that the time taken from drawing to cutting is limited to only a few minutes. Laser inspection with first article reports in less than a minute is offered to ensure that our operations meet your strict quality specifications.

Equipment

33 ton Punch/Laser Capability

Can automatically load/unload 5’ x 10’ material

240 ton 14’ Bending Robot

Capable of automatically bending large/heavy material

Powder Coat Line

Capable of painting 13’ long panels

Unlimited choice for color

Plastic Injection Molding Capabilities

Flexible PVC, ABS, Polycarbonate

Plastic Extrusion Capabilities

Rigid PVC, Flexible PVC, Polyethylene, ABS Polypropylene, Polycarbonate, Santoprene

Tube Bender

Capable of bending square and round tubing

Assembly Area

Capable of completing your assemblies, including any wiring required

Inspection Equipment

Automatic scanning and report generation. Also capable of reverse engineering of your part

We also have a complete wire assembly area and work closely with UL. We would be pleased to assist in getting your product UL approved if necessary.

Creating VALUE for our customers:

Quality and consistency

Fast production capabilities / Reduced lead times

Quick turnaround times – from initial design to final part production

Comprehensive prototyping capabilities

Precise part production and repeatability

Advanced design software allows smooth, efficient process from design conception to finished parts

Eco-friendlyoperations: lower power consumption, reduced scrap

Proud heritage of Manufacturing in the USA